Xjet on its Safe, Eco-Friendly Process for Ceramic and Metal 3D Printed Parts

Already, the 3D printing industry has seen a rapid increase in commercialization. This has led to huge growth in certain verticals such as ceramics or metal. According to a recent study, the global ceramic 3D printing market is expected to reach 384 millions USD in 2025. The metal market, which is considered one of the fastest growing in the AM sector, is expected to surpass $18B by 2032 for understandable reasons.

The above-mentioned materials allow for complex part creation and superior mechanical properties through 3D printing. NanoParticle Jetting™, the signature process of AM 3D printing leader XJet, is compatible with both ceramics and metals, offering an automated, safe, environmentally friendly path toward scale manufacturing of high-quality, geometrically complex parts. We spoke with the company’s CMO, Guy Zimmerman, to learn more about the technology, its benefits, and XJet’s unique approach.

3DN: Would you like to introduce yourself and Xjet

Guy Zimmerman is my name. As Xjet prepares for its growth, I was recently appointed as CMO. My experience is diverse, but my most important one is in international business. Xjet, a 3D printer company, is currently focusing on the hardest segment of additive manufacturing: metals and ceramics. High quality, ready to use metal and ceramic parts that go into manufacturing and not into prototyping: that is the ambition using our own patented NanoParticle Jetting™ (NPJ) technology.

Xjet, a 3D printer maker, is currently addressing the most difficult segment of additive manufacturing: metals and ceramics. High quality, ready to use metal and ceramic parts that goes into manufacturing and not into prototyping, that is the ambition using our own patented NanoParticle Jetting™(NPJ) technology.

Guy Zimmerman

3DN: How does NPJ function? It has many benefits.

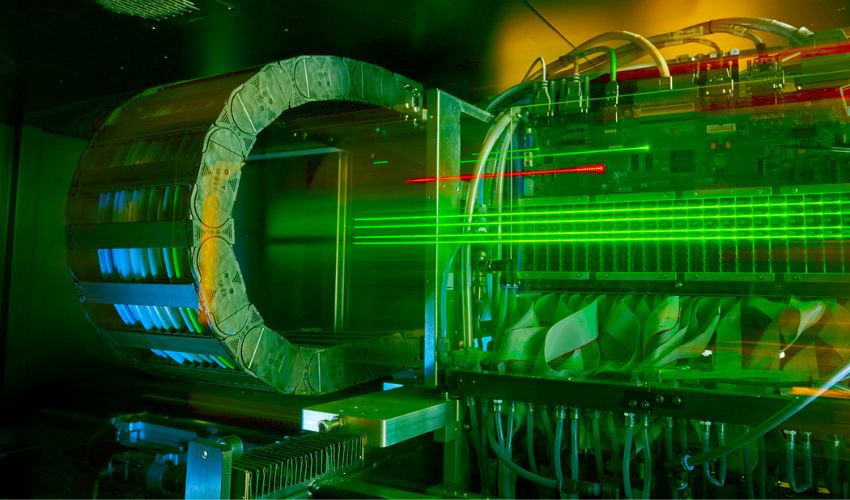

NPJ delivers clean, automated manufacturing of high quality parts in metal and ceramics without involving powders, manual labor, or post processing . What enables this breakthrough is XJet’s unique additive manufacturing process based on nano-particles direct material jetting, which print high-resolution parts using the toughest materials in scale. This process uses both main and support materials, which is a new approach to AM.

Let’s dive a little deeper into the printing procedure. It is called Print-Wash -Sinter. It works by using procurable material that is based on nanoparticles. We can simultaneously print the support and material, which are both very tough but highly soluble. After the build is complete, we wash the support in water using an automated process. Final sintering is performed in an industry furnace at a lower temperature than with powder-based solutions. This enables the highest complexity, accuracy and a level surface. Design-related limitations are also removed. Technology and use of thin nanoparticle layer and soluble supports enable complex and precise geometries. This includes internal components. It also opens up new possibilities for design that were previously considered unimaginable.

Xjet has a wide range of great solutions

This results in high-quality and precise parts right from the start. ThE-printed parts don’t require additional processing. You can print, wash and sinter your parts just like the XJet slogan.

Nanoparticles also have the advantage of being able to Print thin layers. The density level is significantly higher compared to other additive technologies, reaching highest levels of material purity, density and surface smoothness. This significantly improves the parts’ performance and reduces the sintering effect.

The sintering process transforms the particles into real material. This can lead to substantial shrinkage. With XJet’s technology, the process is done at a temperature lower than 200C, which saves time, boosts density, and reduces isotropic and overall shrinkage. Shrinkage remains the same along the x, y and z axes, resulting in no distortions in the final part. This innovative and proprietary technology is used to pack the parts in a high-throughput manufacturing process. The digital and automated manufacturing process results in higher-quality parts than a manual process.

3DN: What are the applications for Xjet’s solutions?

We are collaborating with market leaders customers to target specific verticals in each of the three industrial domains, Industrial, Medical and Consumer.

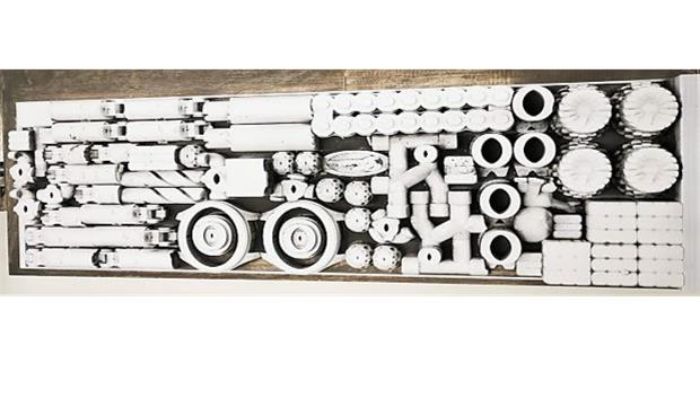

Ceramics are mainly Alumina and Zirconia. They offer excellent resistance to heat and corrosion, and provide electrical isolation. This freedom opens up new opportunities for industrial applications, such as. Manufacturing equipment for semiconductors as well heat exchangers, electricity connectors, waveguard antennas and parts of electrical boards.

Formnext 2022 was attended by Xjet

We are expanding our presence in dental crowns and implants, which are another prominent vertical. This is one of today’s fastest growing markets. In consumer goods we focus on high value wearables like high-end earbuds (which is an intriguing application, as the printed parts are very small, nonconductive, and customized to offer top acoustic qualities), and luxury watches.

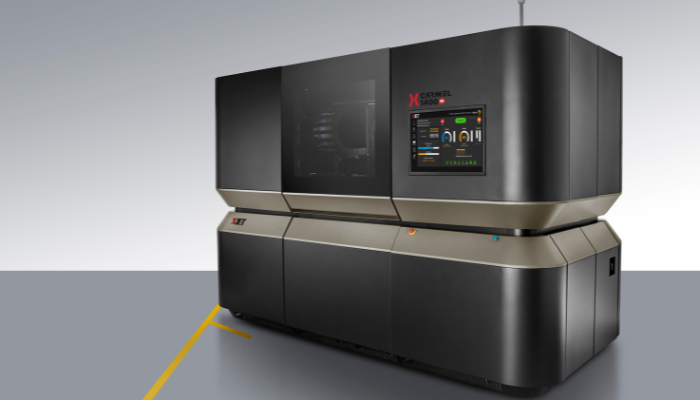

Our high-performance Carmel1400 ceramic part manufacturing system allows us to make many ceramic parts. We also print the parts ourselves with our machines. Metal has been replaced by traditional MIM, or Metal Injection Molding. It is suitable for parts with short runs as well as high-quality parts.

Our support is broad and includes many applications which require large quantities of parts. This replaces several of the traditional technologies. This includes CNC (Metal Injection Molding), MIM, investment casting and CNC. Our technology is more cost-effective than other central technologies with smaller parts.

3DN: Why did Xjet choose to launch a metallic solution?

We established ceramics technology among the market leaders and technical experts in ceramics. Then we developed the metal portion of our portfolio using two of the most popular stainless steel materials. Metal is an even larger market. Developing the metal solution was more challenging, but we’ve reached unprecedented performance levels, even better than ceramics. After undergoing a lengthy evaluation, the metal solution was finally introduced to market in early 2022.

It is now available, and we showcased it at Formnext 2022 with testimonials from the technology’s leading beta users. This metal solution is a viable alternative to multiple powder-based technology solutions and offers clear benefits as an automated, clean process that can be used in many sectors.

Xjet’s metal solution

There are many advantages to this technology. The first is that we have developed soluble support material which can be used with the metal. This is an enormous advantage to many users. A second benefit is the excellent surface quality of the part. This is possible without any extra processes. This third benefit can produce highly complicated parts with precision, which is a tremendous advantage in many areas.

We can also print the whole wristband of an expensive watch made from stainless steel. It might need a little bit of polishing, but that’s it. It is possible to print wristband bearings in the part without having to assemble them. NJP allows you to produce high-quality, precision parts in metal. The focus of our users is to make high-performance parts that are accurate in a variety of consumer-facing sectors.

3DN: Sustainability is another aspect of which you can be proud. What exactly makes it eco-friendly?

The first is safety. They are safe because they are in sealed bottles and contain no harmful particles. It’s a safe process for those who operate it, which is not the case for many AM and traditional processes. It uses only the required amount of material. The additive process does not waste material.

The support material can safely be drained as it is water-soluble. Although it contains minerals, the material is safe enough to be used as drinking water. It almost eliminates the need for waste disposal, making it safer for people and the environment.

Sintering, last but not least is much more sustainable than other methods. This is the part that consumes the most energy, however, because it’s done at lower temperatures and for shorter periods of time, we can save a lot. NJP is one the most eco-friendly metal and ceramic processes.

3DN: Last words to our readers

NPJ technology has three main advantages. NPJ technology has three main advantages. It is safer, more accurate and can achieve higher densities thanks to nanoparticles embedded in the ink. Second, the benefits are rooted in building. By printing thin layers you can achieve incredible complexity and Design for Functionality. The third benefit is the green one. You can clean our parts with water.

Three steps are required to print, wash and sinter the material. Moving forward, we believe the technology will become a major part in the digital transformation of ceramic and metal, industrial, high-quality, complex parts manufacturing. Find out more information about XJet HERE, or watch the video below for a better understanding of how our technology works.

Let us know what you think about Xjet. Let us know in a comment below or on our LinkedIn, FacebookPlease see the following: Twitter pages! Don’t forget to sign up for our free weekly Get the NewsletterReceive the latest news on 3D printing directly to your inbox All our videos can be found on our YouTube channel.

*All Photo Credits: Xjet