The Lumia X1 Is Overcoming Limitations in Resin 3D Printing With an Innovative Hybrid Process

Since stereolithography, the primary additive manufacturing know-how, was invented within the early 80s, there has all the time been a spot for resin 3D printing within the sector. At the moment, numerous completely different variations exist however the two commonest stay DLP and SLA. Nevertheless, it may be troublesome for customers to know which one to decide on. Whereas SLA permits for extremely detailed and exact components, it’s sluggish as a result of utilization of a laser to remedy level by level. In the meantime DLP, which makes use of a projector or mild generator, is quick however the finish components shouldn’t have the identical accuracy. However what if these two applied sciences might be mixed to eradicate the constraints and permit customers to simply reap the advantages? Properly, due to Axtra3D, this has turn into a actuality. Within the Lumia X1 3D printer the corporate has built-in a brand new 3D printing course of named Hybrid PhotoSynthesis (HPS), which mixes each DLP and SLA permitting for simpler and larger-scale resin 3D printing.

It isn’t the primary time that we’ve advised you about Axtra3D. The startup was based in 2021 by Gianni Zitelli and Praveen Tummala and is predicated in each Charlotte, North Carolina and Vicenza, Italy. With their revolutionary Hybrid PhotoSynthesis (HPS) and TruLayer Expertise, Axtra3D hopes to open a brand new realm of potentialities for the 3D printing business, promising a big construct space, high-resolution, quick speeds, spectacular floor high quality and steady printing (options that up till now had typically been mutually unique). Not solely that, however according to its values, the corporate can be dedicated to holding the Lumia X1 3D printer utterly open from a parameter entry and materials perspective, giving larger freedom to customers. Moreover, it plans to disrupt the established order in subject service with 24/7 help request response inside 60 minutes and the usage of AR know-how to resolve a excessive proportion of points remotely and rapidly. However what precisely are you able to count on from the corporate’s first answer, the Lumia X1?

The Lumia X1 from Axtra3D combines SLA and DLP in an revolutionary, hybrid course of

Combining Pace and Accuracy in One Course of

After all, one of many principal advantages of the Lumia X1 3D printer is undoubtedly the 3D printing know-how itself. The difficulties in selecting a resin know-how as a result of many tradeoffs present between them, precision versus velocity notably, are well-known. Nevertheless, with HPS, this subject is a factor of the previous. The sunshine engine know-how combines each DLP and SLA in a single co-axial system.

The best way the know-how works is that it integrates each a picture generator and a laser. These two mild sources are in a position to work synchronously on the identical wavelength on the similar picture airplane planarity. The picture generator cures the majority of the cross-section, or “Flash Hatching.” This enables for the velocity of DLP. On the similar time, the laser works to create the border contours for higher floor high quality and accuracy at a 50-micron decision. By leveraging each, Axtra3D has managed to, in their very own phrases, “unlock unparalleled print velocity, high quality and accuracy.” Furthermore, it’s attainable to scale the know-how for giant platforms as effectively, permitting for a bigger construct quantity which is commonly a rarity with many resin 3D printing processes.

After all, HPS just isn’t the one revolutionary know-how within the Lumia X1. The printer additionally integrates one other characteristic that it claims will assist revolutionize resin 3D printing, TruLayer know-how. It ought to come as no shock {that a} key disadvantage in all resin photopolymer processes is that the layers can stick on the plate, inflicting delays. TruLayer has been designed to beat this.

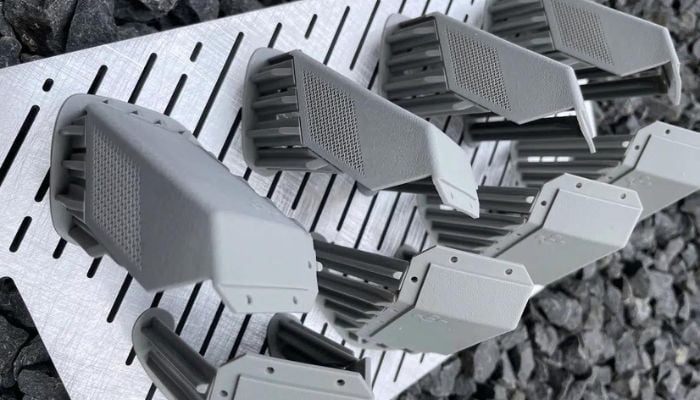

Impellers (left) made on the Lumia X1 whose construct plate is proven on the proper

Primarily, within the Lumia X1, Axtra3D has integrated a trio of sensors onto the glass plate beneath the printer’s membrane, thus eradicating inter-delays whereas amplifying the printing velocity twofold. However how? Properly, the innovation works by guaranteeing the swift detachment of the print layer from the vat membrane, eradicating constraints on measurement and bulk of the cross-sections. Because of this, the vat membrane has a permanent high quality and bolstered longevity all with the potential to print with even extremely viscous resins.

Paul Spolianksy, CRO of Axtra3D, additional explains “Since implementing our TruLayer Expertise, we’ve observed a big efficiency benefit over our rivals. We’re excited to supply our prospects with top-notch decision, unmatched accuracy, and quick print speeds that not solely improve manufacturing purposes but additionally make them economically viable.”

Further Options of the Lumia X1

Past the combination of TruLayer know-how and Hybrid PhotoSynthesis within the Lumia X1 3D printer, the machine has numerous different traits that make it enticing to customers. Constructed to industrial requirements, the answer is anticipated to have a ten+ 12 months working life. On the similar time, it provides numerous security options together with air flow, a magnetic interlock system, a UV shielded viewing window and naturally an emergency cease button. It additionally boasts options just like the Intelli-Cartridge, a double Z-Axis, built-in 4k chamber digital camera, giant graphic consumer interface and each a web-based and offline mode.

Elements made with the Lumia X1 are in a position to be made rapidly whereas nonetheless being correct

The Intelli-Cartridge specifically has been pointed to by the corporate as an thrilling innovation. It goals to simplify and automate the 3D printing course of by actively managing the resin within the printer by shelling out materials within the vat and accumulating extra materials in addition to stirring, heating and filtering. Moreover, due to the Intelli-Cartridge, the quantity of resin that can be utilized for printing not solely will increase to a complete of 8 liters however eliminates the necessity for handbook top-ups.

Past this, it additionally minimizes waste by taking out further resin, filtering it after which returning it to the cartridge. With computerized mixing as effectively, the Intelli-Cartridge ensures constant ranges of fabric in every layer whereas infrared heaters management the temperature. All collectively, the characteristic performs an essential position in bettering the effectivity and comfort of high-volume printing, key components generally that may be seen within the Lumia X1 3D printer general. If you want to study extra in regards to the Axtra3D and the Lumia X1 3D printer, you may go to Axtra3D’s web site HERE or their LinkedIn HERE.

What do you consider the Lumia X1 3D printer from Axtra3D? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to join our free weekly Publication right here, the most recent 3D printing information straight to your inbox! You can even discover all our movies on our YouTube channel.

*All Photograph Credit: Axtra3D