Switch from ‘Hard’ to Easy Automation Changes PharmaMed Automation’s Approach to Robots

Integrator and OEM PharmaMed Automation was requested to construct case labeling tools for a producer of liquid degree sensors and alarm methods. The shopper requested a quick, full-color, on-demand label printer and a quick, versatile, and exact technique of affixing the labels. Answering the decision, PharmaMed designed and constructed a self-contained labeling cell with a shade inkjet label printer, a 6-axis robotic, a {custom} label monitor, {custom} device head, and a conveyor, with all logic residing within the robotic’s built-in controller. This expertise, with a particular request to analyze Epson robotics and printers, snapped PharmaMed out of what it the integrator now considers to be an antiquated devotion to single machines conducting singular duties.

“We preferred to name it exhausting automation as a result of it’s exhausting to do,” jokes Justin Mattson, Gross sales Engineer for PharmaMed Automation. He’s riffing on that conventional course of the place manufacturing unit integrators allocate machines and tools to single, fastened duties. “Exhausting automation is all about rigidity, about constructing one thing that does one factor, and it’s tougher as a result of there’s no flexibility.”

Dustin Hanson, PharmaMed president, agrees. “It’s irritating as a result of there are such a lot of purposes the place a SCARA or 6-axis robotic can be the best way to go, however the funds doesn’t enable it.’” Epson VT6L All-in-One 6-Axis Robotic and Epson ColorWorks CW-C6000P Shade Inkjet Label Printer work collectively to allow exact label placement on an assortment of corrugated circumstances.

Epson VT6L All-in-One 6-Axis Robotic and Epson ColorWorks CW-C6000P Shade Inkjet Label Printer work collectively to allow exact label placement on an assortment of corrugated circumstances.

Mattson’s and Hanson’s expertise with Epson Robots and Epson Colorworks started simply over a 12 months in the past, in 2022, when a liquid degree sensor and alarm producer shopper distinctively requested them to have a look at Epson’s ColorWorks CW-C6000P Shade Inkjet Label Printer together with an Epson VT6L All-in-One 6-Axis Robotic to print and apply labels. Since that introduction, the integrator has used 10 extra Epson robots in tasks for different purchasers.

“With Epson all-in-one platforms, our complete operation has opened up,” Mattson says.

Paradigm shifting venture

Hanson describes PharmaMed Automation, based mostly in Fargo, North Dakota, as a small and nimble engineering firm that focuses on probably the most difficult manufacturing unit automation tasks.

He says that, when he based PharmaMed with associate Walt Stewart in 2012, “the main focus of the corporate was the manufacturing of {custom}, usually non-robotic, exhausting automation cells for pharmaceutical and medical machine corporations.”

But Hanson was intimately accustomed to robotics and had labored with nearly each model of commercial robotic at one time or one other throughout his profession. “Truly, on the firm I used to be at earlier than we began PharmaMed, we developed our personal SCARA robotic and the software program to regulate it. It was the primary SCARA robotic developed on the Rockwell platform.”

He explains that “the job we do could be very tough, as a result of we’re at all times making an attempt to resolve some new downside that nobody else needs to the touch. It’s a excessive danger, excessive reward sort of enterprise.”

In 2018, he and Mattson based one other firm, Vektor Designs, to serve a extra basic manufacturing base. They merged the 2 companies in 2022.

Working below the Vektor model, Hanson and Mattson took on this new shopper, the producer of liquid degree sensors and alarm methods. The shopper packages these sensors in corrugated circumstances of about 8 x 8 in. in size and width, and both 6 in. or 8 in. in peak. It then labels these circumstances with a self-adhesive label that’s 6 in. broad and 4 in. tall.

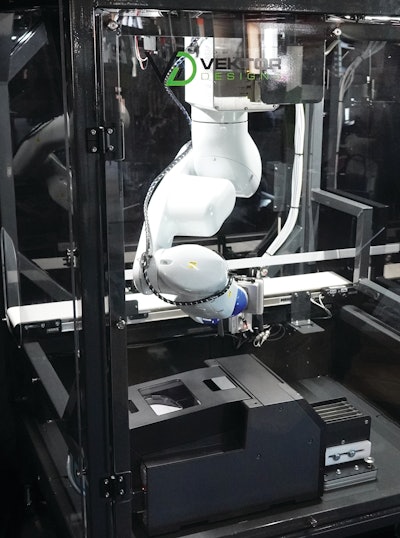

Regardless that the switches are offered via business plumbing contractors, the shopper had been eager to go to a full-color label to set itself aside from rivals. The corporate additionally wished to create a extra constant look than is feasible with hand-applied labels.  Customized self-contained labeling cell with an Epson VT6L All-in-One 6-Axis Robotic and Epson ColorWorks CW-C6000P Shade Inkjet Label Printer and {custom} label monitor, toolhead, and conveyor.

Customized self-contained labeling cell with an Epson VT6L All-in-One 6-Axis Robotic and Epson ColorWorks CW-C6000P Shade Inkjet Label Printer and {custom} label monitor, toolhead, and conveyor.

Most significantly, the shopper was dealing with an enormous staffing problem, with a workforce that had dropped from about 700 previous to COVID-19 to only 400, so an automatic workflow was extremely fascinating.

The shopper, Mattson says, had seen the Epson ColorWorks printer and wished to make use of it on this software.

“You should purchase pre-printed labels and put them onto an off-the-shelf labeling machine, however then each label on the reel goes to be the identical,” he explains. “However this shopper would possibly field up eight of their switches, then field up 10 extra of one other mannequin, and they also want the flexibleness to ship any print run of any amount to the system.”

Mattson additionally says the CW-C6000P is quick and dependable, capable of print, trim, and peel labels 8 in. broad and any peak at as much as 5 in. per second. Utterly digital, it will possibly swap from one label design to a different with out pausing. Moreover, it comes normal with an I/O port so it will possibly simply be built-in onto an automatic system.

“Past the label printing,” Mattson provides, “they noticed that it was a greater choice for them to make use of a robotic arm to choose and place it than any type of fastened machine.”

Whereas exhausting automation is historically cheaper than robotics, the costs of the Epson robots had been engaging to the shopper and the Vektor/PharmaWorks design crew. “As soon as you should purchase a high-quality SCARA for below $10,000, or a 6-Axis for below $15,000, that modifications issues,” Hanson says.

The crew designed a self-contained cell with the ColorWorks printer, a custom-built monitor to hold the labels, and a ceiling-mounted VT6L robotic to choose up every label then apply it to the case, which is carried into place by a Dorner conveyor. The crew designed and constructed their very own pneumatic toolhead, which not solely applies the label however then backs off and faucets it to ensure it’s firmly utilized. Then the conveyor brings up the subsequent case.

“We have now a sensor embedded into the toolhead to confirm {that a} label is current, after which we confirm that it’s been utilized to the case,” Mattson says.

For now, he says, the shopper at all times applies the label into the identical place on the facet of every case, however through the use of a robotic relatively than a set labeling resolution, they know they’ll be capable of fluctuate the case measurement and placement with only a easy software program change.

The shopper, Mattson says, initially ordered two of those self-contained labeling machines, however after they noticed how effectively it labored, they quickly ordered a 3rd.

Change in perspective

Since beginning on the venture, PharmaMed has used Epson robots with three different purchasers, together with two the place they built-in Epson with the Siemens automation platform and one with Rockwell.

“We really used the Epson controller to energy all the labeling cell, nevertheless it’s a small cell with a few air cylinders, the conveyor, and this printer. However actually whenever you begin utilizing a robotic with the key platforms, that’s the place the rubber hits the highway,” Hanson says. “For us that’s huge, and it’s primarily as a result of we’re placing Epson robots into tasks the place we’d not have used any robotic previously. You get to a worth level the place portions can go up and you will get quantity. Quantity, in flip, is how one can get your value down. I do know that’s Epson’s play, and it’s our play as effectively… the rationale we fell in love with the product.”

There are good and unhealthy factors with each product and each enterprise, “however we all know our ache factors,” Hanson says. A giant supply of ache is the difficultly of designing and constructing fastened automation options. “We attempt to eliminate ache, and so we’re prepared to make a change if we discover one thing that works effectively.

“An Epson robotic,” he provides, “has the options and the worth level we want. It’s a superb, dependable product. Programming is easy utilizing the Epson RC+ atmosphere, and it integrates effectively with Siemens and Rockwell, which is essential for us. And it has nice help.”

Would they advocate Epson for different purchasers’ and automation integrators’ packaging tasks?

“Sure,” Hanson says. “For certain.” PW