Amidst a Global Pandemic, DTG Is Stronger Than Ever

COVID-19 was responsible for a boom in online commerce, which led to increased demand of digitally printed clothing. This article provides a quick discussion on the shifting consumer purchasing habits. It also explores the reasons why digital print-on-demand has accelerated and how GTM and supply chains will change.

- COVID-19 enhanced brick-and mortar store closings, at a moment when they were common. These stores won’t reopen after lifting restrictions.

- The web-to print and workflow automation technologies allow customers to create their own designs.

- 2020 direct-to-garment print volumes exceeded those from 2019, fueled by unprecedented increases in ecommerce sales—primarily in North America.

- Manufacturers and retailers will be more dependent on direct-to garment technologies in a post-pandemic environment for trend analysis and product development.

By Mike Bertini

Introduction

Are you able to recall how life was before COVID-19 Sometimes it’s hard to recall what things were like before we had to worry about facemasks, social distancing, or transforming our homes into virtual workspaces. In the last 14 months so much has happened, even in how we shop to imprint activewear. Many turned to the Internet to search for new fashion trends and graphic designs as stores were subject to lockdowns. They discovered an online marketplace with seemingly limitless product choices and personalized shopping that gave them a new sense of freedom. The space in physical stores was no longer sufficient for them; they had unlimited choices.

Consumers weren’t the only ones who quickly learned to adapt. Retailers and manufacturers had to change their strategies for go-to-market as well as supply chain management when off-shore purchases were delayed or cancelled. They left with very few products to sell. JIT manufacturing was vital because small orders could be made by local facilities using digital printing technologies. Direct-to garment (DTG), a method of producing on-demand, became a valuable tool for real-time trend analysis as well as graphics testing.

As a result, print service providers (PSPs) experienced unexpectedly high order volumes, leading to increased demand for new devices in the second half of 2020—particularly in North America. This news was good for OEMs, as many ended 2020 with significant year-over–year growth despite the pandemic.

The Dynamic of Choice

It wasn’t long ago that limited choices dominated the decorated apparel landscape. In the hope of forecasting future trends, brands would aim to have little inventory on their shelves and hit the mark each season. In today’s marketplace, though, digital printing technologies enable consumers to create and personalize their apparel with the help of online web-to-print solutions. DTG has empowered consumers to create personalized graphics and products that were once out of reach—a paradigm shift that will forever change the dynamics of how decorated apparel is purchased. After all, who doesn’t like more choices? The few are losing purchasing power and the majority of consumers are taking control of their buying decisions.

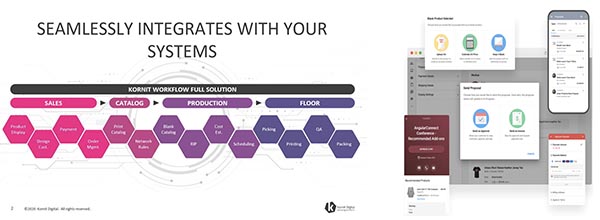

OEMs have seized the chance to invest more in prepress and afterpress solutions. These enable PSPs become fully-automated microfactories capable of printing and managing orders and fulfilling fulfillment. Kornit’s acquisition of Custom Gateway, a cloud-based workflow solution for digital PSPs, garnered attention in 2020 and uncovered the need for workflow solutions that enable consumers to customize their decorated apparel, while simultaneously sending the order processing and print jobs directly to press. Wasatch software has been teamed up with Epson to automate workflows. This integration allows for file processing and barcoding as well as on-press scanning. InkSoft and third-party platforms such as ecommerce are making waves, as well as OEMs working with software vendors. Digital printing will continue to grow in popularity as consumers demand more customization and choice.

Solution from Kornit/Custom Gateway (left), and InkSoft(right).

What the Pandemic Did to Everything

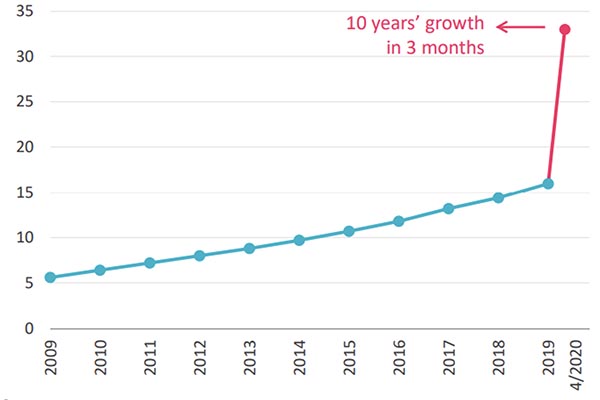

Before COVID-19, brick-and mortar sales had suffered at an alarming rate from e-commerce. Store closures were commonplace as mom-and-pop boutiques—and even major retailers—struggled to survive, even in a booming economy. The pandemic sent this trend into overdrive as most remaining stores were forced to close for months at a time—and many of these will not reopen even after all restrictions are lifted. As a result, ecommerce sales grew at unprecedented levels, achieving a staggering 10 years’ worth of growth during a 90-day period.

Growth in Ecommerce

Source: The Reinvention of Retail; McKinsey & Company 2020

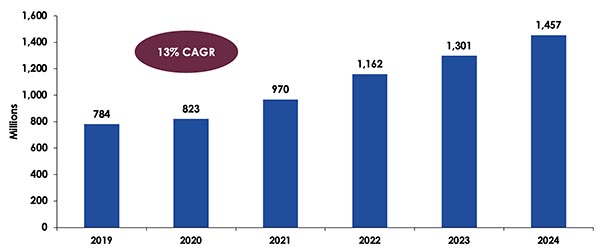

As consumers experienced the convenience, fast shipping, and seemingly endless array of products at their fingertips, they became hooked—if they weren’t already. As retailers and PSPs began to market on-demand graphic products in the DTG sector, they saw a surge in sales as they offered a broad range of customized garments and color options. The initial forecasts for 2020 DTG volume were 17% lower than 2019 as COVID-19 was enacted. Thanks to accelerated ecommerce and digital print on-demand expansion, however, 2020 outpaced 2019 by about 5% as the second half of the year exploded—and the lion’s share of this occurred in North America. The DTG printing revolution is gaining momentum with a forecasted 13% compound annual growth rate (CAGR) from 2019–2024. DTG devices generated an estimated 823,000,000 impressions in 2020. They are predicted to generate over 1.4 Billion impressions by 2024.

DTG printed garments—global volume forecast

Source: DTG Market Forecast 2019-2024; Keypoint Intelligence 2020

Strategie for a New Future

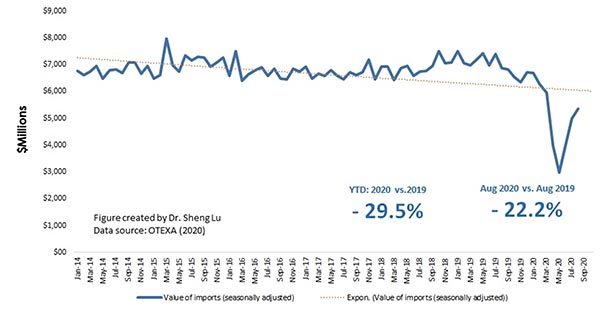

As the world looks forward to a post-pandemic future, it’s helpful to reflect on lessons learned from the past. COVID-19’s effects were an admonition of the fragility of our supply chains. The global decline in investment and trade was so severe that the US and China saw drops of up to 50%. Purchase orders were delayed or cancelled as factories closed down. Normal flow of goods was disrupted, mostly due to a cost-driven single source model. US apparel imports fell.

Imports of US clothing from other countries (by value).

Source: https://shenglufashion.com

Many companies were forced to change how they source their products. Digital printing technology allowed retailers and brands to create a buy-activated manufacturing process using domestic digital printing. They discovered that DTG goes beyond on-demand printing. The traditional buying season is rapidly disappearing in an environment of speed-to market and consumer demand for new items every day. Brands and retailers can have both the digital and analog worlds. After determining the top sellers, they will be able to offer new graphics online.

DTG has revolutionized product development in digital age. Retailers live and die by inventory management, and DTG is perhaps the most revolutionary tool for real-time trend analysis and graphics testing—with virtually no finished inventory risk. DTG technology has been a huge success for brands like Life Is Good. Hot Topic and other retailers are now using DTG to sell online, replenish store shelves, or fulfill immediate orders out of stock. More retailers and brands are likely to follow their lead in the second half 2021.

Let’s get to the bottom

DTG’s future is bright and DTG is ready for growth. Digital printing has revolutionized the way that decorated clothing is bought. This was possible thanks to accelerated ecommerce growth and closing down stores. Consumers can personalize their items with web-to-print technology. OEMs are investing more in workflow automation so that PSPs can keep up. In the midst of an over-aggravating pandemic, retailers and brands found silver linings. DTG was discovered by retailers and brands as an effective tool to trend analysis, graphic testing, and on-demand printing. DTG is still in its infancy, and it will be exciting to see how it continues to evolve—so stay tuned!

Mike Bertini is the Director of Textile and Direct-to-Garment/Direct-to-Fabric Printing at Keypoint Intelligence. Market research, forecasting and custom consulting are some of his responsibilities. He also creates editorial content and reports related to digital textile printing. Prior to joining Keypoint Intelligence, Bertini served as Senior Product Manager, DTG at Life Is Good Clothing Co. His accomplishments at Life Is Good include spearheading a new textile digital printing facility including budget, layout, process flow, P&L, ERP implementation, and quality assurance standards.